Welcome to Wuxi Hongye New Material Co., Ltd !

Tel : +86 180 1478 0128 Email:info@hongye-metal.com

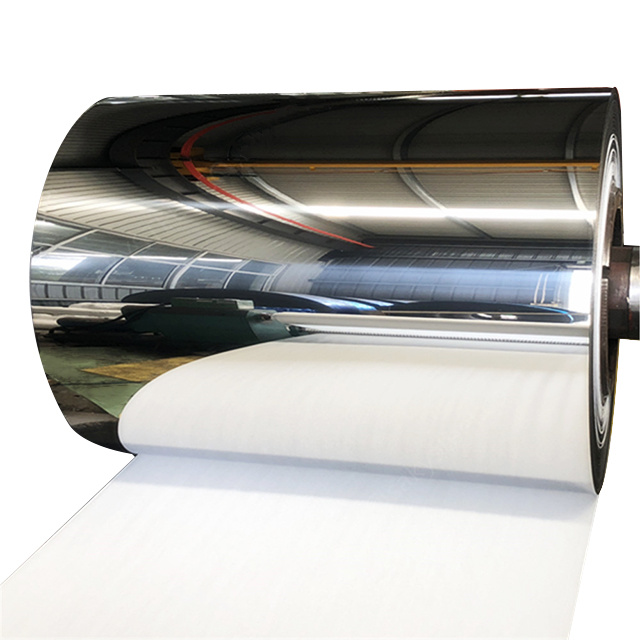

2507 Duplex Stainless Steel Coil

Thickness: 1.2mm – 10mm, etc.

Width: 600mm – 2000mm, the narrowed products pls check in strip products

Max coil weight: 40MT, etc.

Coil ID: 508mm,610mm, etc.

Finish: NO.1, 1D, 2D, #1, hot rolled finished, black, Anneal and pickling, mill finish

Width: 600mm – 2000mm, the narrowed products pls check in strip products

Max coil weight: 40MT, etc.

Coil ID: 508mm,610mm, etc.

Finish: NO.1, 1D, 2D, #1, hot rolled finished, black, Anneal and pickling, mill finish

Alloy 317LMN (UNS S31726) is an austenitic chromium-nickel-molybdenum

stainless steel with corrosion resistance superior to 316L and 317L. The higher

molybdenum content, combined with an addition of nitrogen, provides the alloy

with its enhanced corrosion resistance, especially in acidic chloride containing service.

stainless steel with corrosion resistance superior to 316L and 317L. The higher

molybdenum content, combined with an addition of nitrogen, provides the alloy

with its enhanced corrosion resistance, especially in acidic chloride containing service.

Thickness:0.2mm-18mm

Width:200mm,500mm,1000mm,1219mm,1500mm,2000mm,2500mm,3000mm, etc

Length:C

Products can be customized

Surface:BA,2B,NO.1,NO.4,4K,HL,8K

Standard:ASTM,AISI,JIS,GB, DIN,EN

Width:200mm,500mm,1000mm,1219mm,1500mm,2000mm,2500mm,3000mm, etc

Length:C

Products can be customized

Surface:BA,2B,NO.1,NO.4,4K,HL,8K

Standard:ASTM,AISI,JIS,GB, DIN,EN

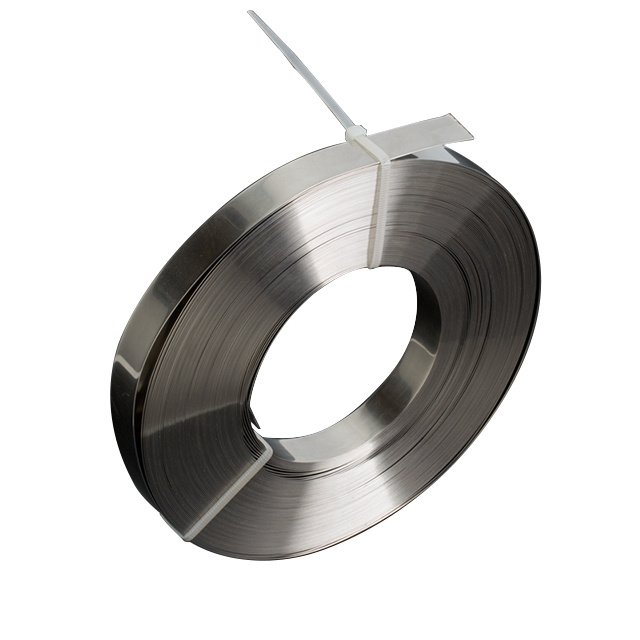

430 Stainless Steel Coil Strip

430 stainless steel is a general steel with good corrosion resistance.

Its thermal conductivity is better than that of austenite, its coefficient

of thermal expansion is smaller than that of austenite, heat fatigue

resistance, addition of stabilizing element titanium, and good mechanical

properties at the weld.

Its thermal conductivity is better than that of austenite, its coefficient

of thermal expansion is smaller than that of austenite, heat fatigue

resistance, addition of stabilizing element titanium, and good mechanical

properties at the weld.

201 stainless steel coil has certain acid and alkali resistance with high density, polishing,

no bubbles, no pinholes and other characteristics. It is a high-quality material for the production

of various watch cases, strap and bottom covers.

no bubbles, no pinholes and other characteristics. It is a high-quality material for the production

of various watch cases, strap and bottom covers.

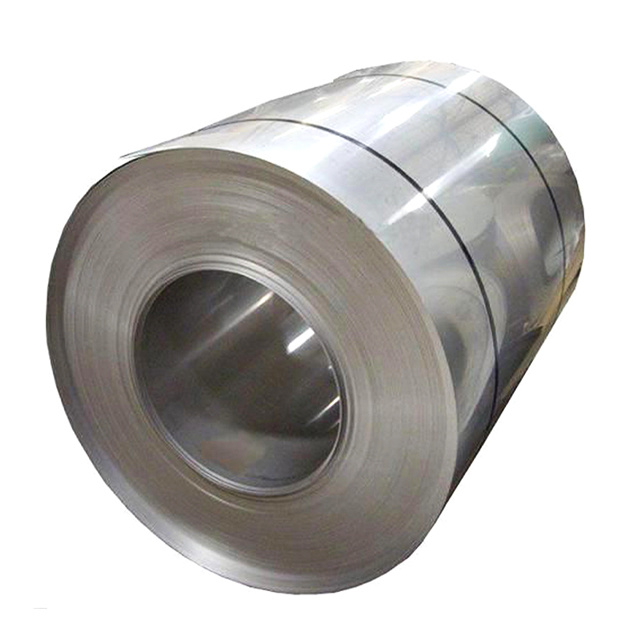

202 Stainless Steel Coil Strip

202 stainless steel is a kind of low nickel high manganese stainless steel in 200 series stainless steel.

Grade: 201, 202, 301, 302, 303, 304,304L,316,316L,409,430

Tolerance: ±1%

Delivery Time: 7-14 days

Grade: 201, 202, 301, 302, 303, 304,304L,316,316L,409,430

Tolerance: ±1%

Delivery Time: 7-14 days

In addition to the improved corrosion resistance compared

with the 300 series stainless steels duplex steels also have higher strength.

Types popularly: 2205 ,2507.2304 318 323325 327,so on

Duplex stainless steels material could be shaped as coils,plates or sheetsstrips,

wires, pipes or tubes, profiles,bars, angles, and others as specially required customization.

with the 300 series stainless steels duplex steels also have higher strength.

Types popularly: 2205 ,2507.2304 318 323325 327,so on

Duplex stainless steels material could be shaped as coils,plates or sheetsstrips,

wires, pipes or tubes, profiles,bars, angles, and others as specially required customization.

The corrosion resistance, and high temperature strength of 316

stainless steel have been greatly improved due to the addition of Mo element.

The high temperature resistance can reach 1200-1300 degrees and can be used under harsh conditions.

stainless steel have been greatly improved due to the addition of Mo element.

The high temperature resistance can reach 1200-1300 degrees and can be used under harsh conditions.

302 Stainless Steel has slightly higher carbon than

304. 302 stainless steel is an austenitic stainless and

has better corrosion resistance than 301. This is due to

302 having a higher nickel content. 302 can be produced

from soft annealed to full hard.

304. 302 stainless steel is an austenitic stainless and

has better corrosion resistance than 301. This is due to

302 having a higher nickel content. 302 can be produced

from soft annealed to full hard.

Grade 304 stainless steel is generally regarded as the most common austenitic stainless steel.

It contains high nickel content that is typically between 8 and 10.5 percent by weight and a high

amount of chromium at approximately 18 to 20 percent by weight. Other major alloying elements

include manganese, silicon, and carbon.

The remainder of the chemical composition is primarily iron.

It contains high nickel content that is typically between 8 and 10.5 percent by weight and a high

amount of chromium at approximately 18 to 20 percent by weight. Other major alloying elements

include manganese, silicon, and carbon.

The remainder of the chemical composition is primarily iron.

CONTACT US

PROVIDE YOU WITH FREE SOLUTIONS