Welcome to Wuxi Hongye New Material Co., Ltd !

Tel : +86 180 1478 0128 Email:info@hongye-metal.com

1070 aluminum has high plasticity, corrosion resistance, electrical conductivity and good thermal conductivity, but low strength, not through heat treatment to strengthen, cutting is not good, can accept contact welding, gas welding.

Make use of its advantages to manufacture some structural parts with specific performance, such as aluminum foil gaskets and capacitors, electronic tube isolation net, wire, cable protection sleeve, net, wire core and aircraft ventilation system parts and decorative parts.

Make use of its advantages to manufacture some structural parts with specific performance, such as aluminum foil gaskets and capacitors, electronic tube isolation net, wire, cable protection sleeve, net, wire core and aircraft ventilation system parts and decorative parts.

5052 represents the brand of the product, and the word "5" indicates that the modified product belongs to the aluminum-magnesium alloy product.

According to the chemical composition, it can be seen that the magnesium alloy content of the product is between 2.2-2.8%, and the density is 2.68.

Generally, enterprises take the median value of 2.5% magnesium alloy content in the processing process, so this series of aluminum plate can become AlMG2.5.

According to the chemical composition, it can be seen that the magnesium alloy content of the product is between 2.2-2.8%, and the density is 2.68.

Generally, enterprises take the median value of 2.5% magnesium alloy content in the processing process, so this series of aluminum plate can become AlMG2.5.

5083 belongs to Al-Mg-Si alloy, which is widely used, especially in the construction industry.

It is the most promising alloy. Good corrosion resistance, good weldability, good cold processing, and has moderate strength.

The main alloy element of 5083 is magnesium, which has good forming performance, corrosion resistance, weldability and medium strength.

It is the most promising alloy. Good corrosion resistance, good weldability, good cold processing, and has moderate strength.

The main alloy element of 5083 is magnesium, which has good forming performance, corrosion resistance, weldability and medium strength.

7075-T6 aluminum alloy hardness is 150HB, belongs to the high hardness aluminum alloy.

7075T6 aluminum alloy is precision machined aluminum in the United States, one of the most commercially available alloys.

The main alloying element of 7075 series is zinc, which has strong strength, good mechanical properties and anode reaction.

7075T6 aluminum alloy is precision machined aluminum in the United States, one of the most commercially available alloys.

The main alloying element of 7075 series is zinc, which has strong strength, good mechanical properties and anode reaction.

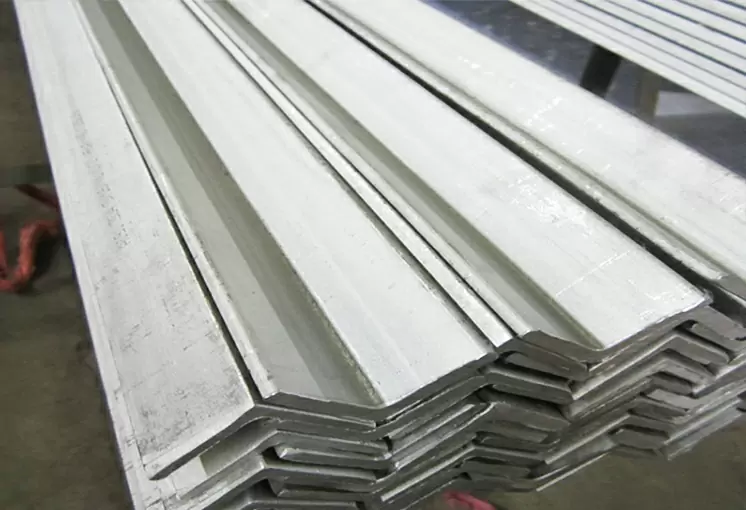

6063 aluminum alloy material.

6063 is a low alloyed Al-Mg-Si high plastic alloy.

The main alloy elements are magnesium and silicon, with excellent machining performance, excellent weldability, extrusion and electroplating, good corrosion resistance, toughness, easy to polish, color film, excellent anodic oxidation effect, is a typical extrusion alloy.

6063 is a low alloyed Al-Mg-Si high plastic alloy.

The main alloy elements are magnesium and silicon, with excellent machining performance, excellent weldability, extrusion and electroplating, good corrosion resistance, toughness, easy to polish, color film, excellent anodic oxidation effect, is a typical extrusion alloy.

6063 aluminum alloy material.

The main alloy elements are magnesium and silicon, with excellent machining performance, excellent weldability, extrusion and electroplating, good corrosion resistance, toughness, easy to polish, color film, excellent anodic oxidation effect, is a typical extrusion alloy.

The main alloy elements are magnesium and silicon, with excellent machining performance, excellent weldability, extrusion and electroplating, good corrosion resistance, toughness, easy to polish, color film, excellent anodic oxidation effect, is a typical extrusion alloy.

7075 aluminum alloy is a cold - treated forging alloy, high strength, far better than mild steel.

7075 is one of the strongest alloys commercially available. Under heat treatment, can achieve very high strength characteristics.

7075 materials are generally added a small amount of copper, chromium and other alloys, the department of 7075-T651 aluminum alloy is particularly top grade, known as the best aluminum alloy products, high strength, far better than any mild steel. The alloy also has good mechanical properties and anode reaction.

7075 is one of the strongest alloys commercially available. Under heat treatment, can achieve very high strength characteristics.

7075 materials are generally added a small amount of copper, chromium and other alloys, the department of 7075-T651 aluminum alloy is particularly top grade, known as the best aluminum alloy products, high strength, far better than any mild steel. The alloy also has good mechanical properties and anode reaction.

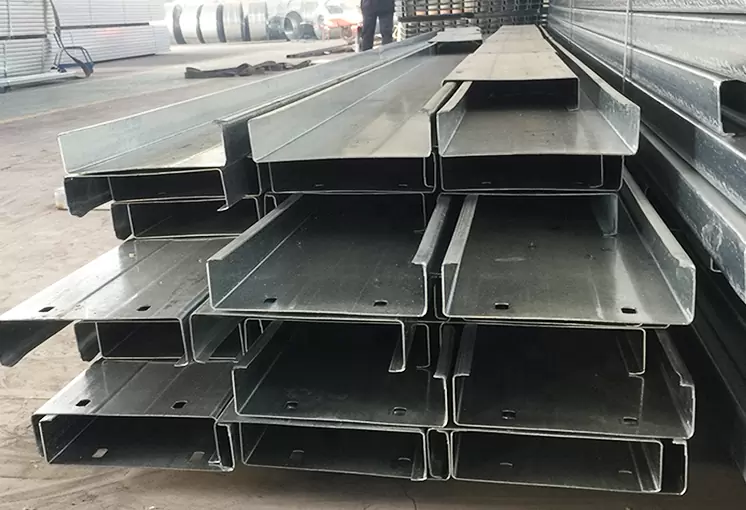

6082 is a heat-treatable alloy with good formability, weldability, machinability and corrosion resistance.

It also has moderate strength and can maintain good operability after annealing. It is mainly used in mechanical structure, including bars, plates, pipes and profiles.

This alloy has similar but not identical mechanical properties to alloy 6061, and its -T6 state has higher mechanical properties.

It also has moderate strength and can maintain good operability after annealing. It is mainly used in mechanical structure, including bars, plates, pipes and profiles.

This alloy has similar but not identical mechanical properties to alloy 6061, and its -T6 state has higher mechanical properties.

5052 aluminum is Al-Mg alloy aluminum, magnesium is the main alloy element in 5052 alloy aluminum

is the most widely used one kind of rustproof aluminum, this alloy has high strength, especially the fatigue strength: High plasticity and corrosion resistance, heat treatment can not be strengthened, in the semi-cold hardening plasticity is good, cold hardening plasticity is low, good corrosion resistance, good weldability,

is the most widely used one kind of rustproof aluminum, this alloy has high strength, especially the fatigue strength: High plasticity and corrosion resistance, heat treatment can not be strengthened, in the semi-cold hardening plasticity is good, cold hardening plasticity is low, good corrosion resistance, good weldability,

The mechanical properties of 2024-T3 aluminum alloy can be significantly improved after heat treatment.

2024 is a typical duralumin alloy in the aluminum-copper-magnesium system. It is a heat-treatable alloy with high strength, easy to work, easy to turn, and moderate corrosion resistance.

2024 is a typical duralumin alloy in the aluminum-copper-magnesium system. It is a heat-treatable alloy with high strength, easy to work, easy to turn, and moderate corrosion resistance.

CONTACT US

PROVIDE YOU WITH FREE SOLUTIONS