Welcome to Wuxi Hongye New Material Co., Ltd !

Tel : +86 180 1478 0128 Email:info@hongye-metal.com

317LMN Steel Plates/Coils

Category:

Stainless Steel Coil

stainless steel with corrosion resistance superior to 316L and 317L. The higher

molybdenum content, combined with an addition of nitrogen, provides the alloy

with its enhanced corrosion resistance, especially in acidic chloride containing service.

Product information

Alloy 317LMN (UNS S31726) is an austenitic chromium-nickel-molybdenum stainless steel with corrosion resistance superior to 316L and 317L. The higher molybdenum content, combined with an addition of nitrogen, provides the alloy with its enhanced corrosion resistance, especially in acidic chloride containing service.

Characteristics:

1;High temperature alloy with high temperature strength.

2;Good resistance to oxidation and corrosion resistance performance.

3;Good fatigue performance, the fracture toughness, plastic.

Organizational characteristics:

High temperature alloy for a single (austenitic) matrix organization, in all kinds of temperature has good stability and reliability of the organization to use.

High temperature alloy quality requirements:

External quality: external contour shape, size accuracy, the surface defect cleaning method.

Internal quality: chemical composition, structure, mechanical and physical and chemical properties.

Mechanical properties: room temperature and high temperature tensile properties and impact toughness, high temperature lasting several creep properties, hardness and high weeks and weeks, creep, fatigue performance under the mutual action of fatigue and the mechanical properties, thermal and corrosion resistance to oxidation.

| Product Name | China 310 317 317L stainless steel plate | |||

| Material | 201,201,301,302,304,304L,309,309S,310,310S,316,316L,316Ti, 317,317L,321,321H,347,347H,409,409L,410,410S,420,430,904L |

|||

| Thickness | Cold rolled:0.3~3.0mm; Hot rolled:3.0~120mm | |||

| Standard Size | 1mx2m,1.22mx2.44m,4'x8',1.2mx2.4m, as request | |||

| Tolerance | Thickness:+/-0.1mm; Width:+/-0.5mm,Length:+/-1.0mm | |||

| Certificates | BV, LR, GL, NK, RMRS,SGS | |||

| Standard | ASTM A240, ASTM A480, EN10088, JIS G4305 | |||

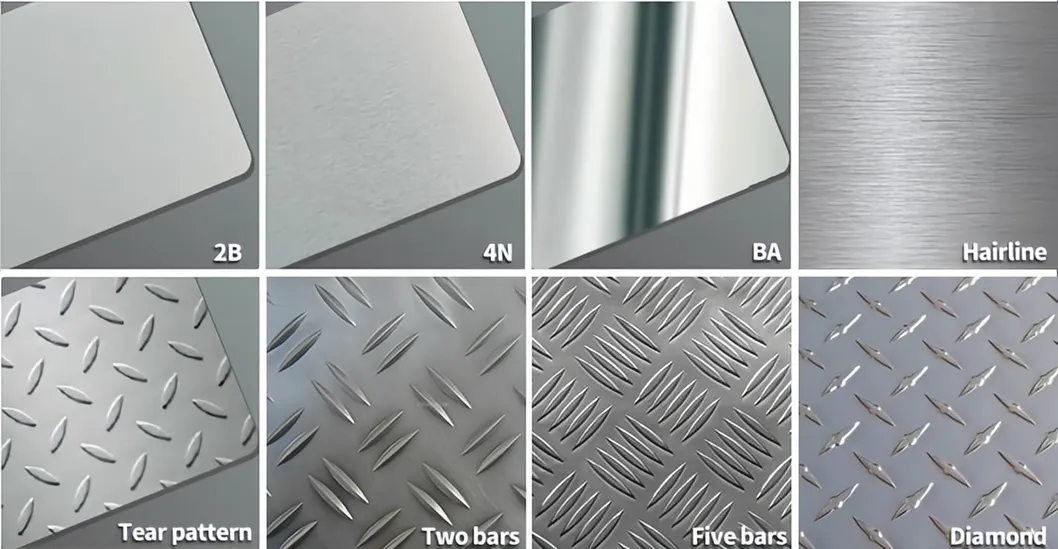

| Finish | NO.1/2B/NO.4/BA/SB/Satin/Brushed/Hairline/Mirror etc. | |||

| Brand | TISCO,BAOSTEEL,LISCO,ZPSS,JISCO,ANSTEEL,etc | |||

| Trade Terms | EXW, FOB, CIF, CFR | |||

| Loading Port | TIANJIN,SHANGHAI, ANY CHINA PORT | |||

| Payment terms | 1) T/T: 30% as deposit, the balance against copy of B/L. | |||

| 2) T/T: 30% as deposit, the balance before shipment. | ||||

| MOQ | 1 ton | |||

Technical data

317LMN(S31726) stainless steel plate/coil Chemical Composition and Mechanical Property

| Grade | C | Mn | P | S | Si | Cr | Ni | Mo | N | Cu | Other Elements |

| 317LMN(S31726) | 0.030 | 2.00 | 0.045 | 0.030 | 0.75 | 17.0 - 20.0 | 13.5 - 17.5 | 4.0 - 5.0 | 0.10 - 0.20 | --- | --- |

| Grade | Tensile Strength, min | Yield Strength, min | Elongation in 2 in. or 50 mm, min, % | Hardness, maxC | Cold Bend°D | |||

| ksi | MPa | ksi | MPa | Brinell | Rockwell B | |||

| 317LMN(S31726) | 80 | 550 | 35 | 240 | 40 | 223 | 96 | not required |

|

Grade |

201/202/301/303/304/304L/316/316L/321/310S/401/409/410/420J1/420J2/430/439/443/444/2205/2507/904L.Etc |

|||

|

Surface Finish |

2B, BA, NO.1, NO.4, 8K, HL, Embossing, Satin, Mirror, ect |

|||

|

Standard |

JIS/SUS/GB/DIN/ASTM/AISI/EN |

|||

|

Technique |

Cold Rolled; Hot Rolled |

|||

|

Thickness |

0.3-4mm cold rolled; 3-16mm hot rolled; 16-100mm hot rolled; Customized according to customer requirements |

|||

|

Width |

1000mm, 1219mm, 1240mm, 1500mm, 1800mm, 2000mm |

|||

|

Length |

2000mm, 2438mm, 2500mm, 3000mm, 6000mm or as required |

|||

|

Color |

Golden, Black, Sapphire Blue, Brown, Rose Gold, Bronze, Silver, ect |

|||

|

Application |

Interior/Exterior decoration; Architectur; Evevator; Kitchen; Ceiling; Cabinet; Advertising nameplate; Roof structure; |

|||

|

Lead Time |

7-15 working days after the receipt of 30% deposit |

|||

|

Payment Terms |

30% TT for deposit,70% TT /70% LC at sight balance before shipment |

|||

|

Price Terms |

FOB, EXW, CIF, CFR |

|||

|

Packing |

Wooden Pallet or according to customer's requirements |

|||

|

Grade |

C |

Si |

Mn |

P |

S |

Ni |

Cr |

Mo |

|

201 |

≤0 .15 |

≤0 .75 |

5. 5-7. 5 |

≤0.06 |

≤ 0.03 |

3.5 -5.5 |

16 .0 -18.0 |

- |

|

202 |

≤0 .15 |

≤1.0 |

7.5-10.0 |

≤0.06 |

≤ 0.03 |

4.0-6.0 |

17.0-19.0 |

- |

|

301 |

≤0 .15 |

≤1.0 |

≤2.0 |

≤0.045 |

≤ 0.03 |

6.0-8.0 |

16.0-18.0 |

- |

|

302 |

≤0 .15 |

≤1.0 |

≤2.0 |

≤0.035 |

≤ 0.03 |

8.0-10.0 |

17.0-19.0 |

- |

|

304 |

≤0 .008 |

≤1.0 |

≤2.0 |

≤0.045 |

≤ 0.03 |

8.0-10.5 |

18.0-20.0 |

- |

|

304L |

≤0.03 |

≤1.0 |

≤2.0 |

≤0.035 |

≤ 0.03 |

9.0-13.0 |

18.0-20.0 |

- |

|

309S |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.045 |

≤ 0.03 |

12.0-15.0 |

22.0-24.0 |

- |

|

310S |

≤0.08 |

≤1.5 |

≤2.0 |

≤0.035 |

≤ 0.03 |

19.0-22.0 |

24.0-26.0 |

- |

|

316 |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.045 |

≤ 0.03 |

10.0-14.0 |

16.0-18.0 |

2.0-3.0 |

|

316L |

≤0.03 |

≤1.0 |

≤2.0 |

≤0.045 |

≤ 0.03 |

12.0 - 15.0 |

16 .0 -1 8.0 |

2.0 -3.0 |

|

321 |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.035 |

≤ 0.03 |

9.0 - 13 .0 |

17.0 -19.0 |

- |

|

630 |

≤0.07 |

≤1.0 |

≤1.0 |

≤0.035 |

≤ 0.035 |

3.0-5.0 |

15.5-17.5 |

- |

|

631 |

≤0.09 |

≤1.0 |

≤1.0 |

≤0.030 |

≤0.035 |

6.50-7.75 |

16.0-18.0 |

- |

|

904L |

≤2.0 |

≤0.045 |

≤1.0 |

≤0.035 |

- |

23.0·28.0 |

19.0-23.0 |

4.0-5.0 |

|

2205 |

≤0.03 |

≤1.0 |

≤2.0 |

≤0.030 |

≤0.02 |

4.5-6.5 |

22.0-23.0 |

3.0-3.5 |

|

2507 |

≤0.03 |

≤0.8 |

≤1.2 |

≤0.035 |

≤0.02 |

6.0-8.0 |

24.0-26.0 |

3.0-5.0 |

|

2520 |

≤0.08 |

≤1.5 |

≤2.0 |

≤0.045 |

≤0.03 |

0.19 -0. 22 |

0.24 -0.26 |

- |

|

410 |

≤0.15 |

≤1.0 |

≤1.0 |

≤0.035 |

≤0.03 |

- |

11.5-13.5 |

- |

|

430 |

≤0.1 2 |

≤0.75 |

≤1.0 |

≤ 0.040 |

≤0.03 |

≤0.60 |

16.0 -18.0 |

- |

| Stainless Steel(austenitic type) | ||||||||||

| USA | Germany | CHINA | Japan | Great Britain | France | Italy | Spain | Sweden | ||

| AISI/SAE | W.-nr. | DIN | GB | JIS | BS | EN | AFNOR | UNI | UNE | SS |

| 304L | 1.4306 | X2CrNi1911 | 0Cr19Ni10 | SUS340L | 304S11 | - | Z2CN18.10 | X2CrNi18.11 | - | 2352 |

| 304 | 1.435 | X5CrNi189 | 0Cr18Ni9 | SUS304 | 304S11 | 58E | Z6CN18.09 | X5CrNi1810 | F.3551/F.3541/F.3504 | 2332 |

| 303 | 1.4305 | X12CrNiS188 | 1Cr18Ni9MoZr | SUS303 | 303S21 | 58M | Z10CNF18.09 | X10CrNiS18.09 | F.3508 | 2346 |

| 301 | 1.431 | X12CrNi177 | Cr17Ni7 | SUS301 | - | - | Z12CN17.07 | X12CrNi1707 | F.3517 | 2331 |

| 316 | 1.4401 | X5CrNiMo1810 | 0Cr17Ni11Mo2 | SUSU316 | 316S16 | 58J | Z6CND17.11 | X5CrNiMo1712 | F.3543 | 2347 |

| 316LN | 1.4429 | X2CrNiMoN1813 | 0Cr17Ni13Mo | SUSU316LN | - | - | Z2CND17.13 | - | - | 2375 |

| 316LN | 1.4435 | X2CrNiMo1812 | 0Cr27Ni12Mo3 | SCS16/SUS316L | 316S13 | - | Z2CND17.12 | X2CrNiMo1712 | - | 2353 |

| 317L | 1.4438 | X2CrNiMo1816 | 0Cr19Ni13Mo | SUS317L | 317S12 | - | Z2CND19.15 | X2CrNiMo1816 | - | 2367 |

| 321 | 1.4541 | X10CrNiTi189 | 1Cr18Ni9Ti | SUS321 | 321S12 | 58B | Z6CNT18.10 | X6CrNiTi1811 | F.3553/F.3523 | 2337 |

| 347 | 1.455 | X10CrNiNb189 | 1Cr18Ni11Nb | SUS347 | 347S17 | 58F | Z6CNNb18.10 | X6CrNiNb1811 | F.3552/F.3524 | 2338 |

| 316Ti | 1.4571 | X10CrNiMoTi1810 | Cr18Ni12Mo2T | - | 320S17 | 58J | Z6CNDT17.12 | X6CrNiMoTi1712 | F.3535 | 2350 |

| 309 | 1.4828 | X15CrNiSi2012 | 1Cr23Ni13 | SUH309 | 309S24 | - | Z15CNS20.12 | X6CrNi2520 | - | - |

| 310S | 1.4845 | S12CrNi2521 | 0Cr25Ni20 | SUH310 | 310S24 | - | Z12CN2520 | X6CrNi2520 | F.331 | 2361 |

| 321 | 1.4878 | X12CrNiti189 | 1Cr18Ni9Ti | SUS321 | 321S32 | 58B,58C | Z6CNT18.12B | X6CrNiTi1811 | F.3523 | - |

| Stainless Steel(Ferrite type/Martensitic type) | ||||||||||

| USA | Germany | CHINA | Japan | Great Britain | France | Italy | Spain | Sweden | ||

| AISI/SAE | W.-nr. | DIN | GB | JIS | BS | EN | AFNOR | UNI | UNE | SS |

| 403 | 1.4 | X7Cr13 | 0Cr13/1Cr12 | SUS403 | 403S17 | - | Z6C13 | X6Cr13 | F.3110 | 2301 |

| 410 | 1.4006 | X10Cr13 | 1Cr13 | SUS410 | 410S21 | 56A | Z10C14 | X12Cr13 | F.3401 | 2302 |

| 430 | 1.4016 | X8Cr17 | 1Cr17 | SUS430 | 430S15 | 60 | Z8C17 | X8Cr17 | F.3113 | 2320 |

| - | 1.4034 | X46Cr13 | 4Cr13 | SUS420J2 | 420S45 | 56D | Z40CM/Z38C13M | X40Cr14 | F.3405 | 2304 |

| 431 | 1.4057 | X22CrNi17 | 1Cr17Ni2 | SUS431 | 431S29 | 57 | Z15CNi6.02 | X16CrNi16 | F.3427 | 2321 |

| 430F | 1.4104 | X12CrMoS17 | Y1Cr17 | SUS430F | - | - | Z10CF17 | X10CrS17 | F.3117 | 2383 |

| 434 | 1.4113 | X6CrMo17 | 1Cr17Mo | SUS434 | 434S17 | - | Z8CD17.01 | X8CrMo17 | - | 2325 |

| 405 | 1.4724 | X10CrA113 | 0Cr13AI | SUS405 | 403S17 | - | Z10C13 | X10CrA112 | F.311 | - |

| 430 | 1.4742 | X10CrA118 | Cr17 | SUS430 | 430S15 | 60 | Z10CAS18 | X8Cr17 | F.3113 | - |

| EV8 | 1.4871 | X53CrMnNiN219 | 5Cr2Mn9Ni4N | SUH35 | 349S54 | - | Z52CMN21.09 | X53CrMnNiN219 | - | - |

| ASTM Specification | Description | Applicable Grades/Materials | Main Applications | Common Thickness |

| ASTM A240 / A240M | Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip | Includes grades like 304, 304L, 316, 316L, 310S, 321, 410, 420, 430, etc. | General applications, pressure vessels, food processing equipment, etc. | Thickness: 0.5mm to 100mm, finishes: cold-rolled, hot-rolled, polished, etc. |

| ASTM A480 / A480M | General Requirements for Flat-Rolled Stainless and Heat-Resisting Steel Plate, Sheet, and Strip | Covers flat plates, sheets, and strips of stainless steel | General requirements for size, tolerances, mechanical properties, etc. | Thickness: Typically 0.5mm to 100mm, different surface finishes |

| ASTM A262 | Practice for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels | Primarily used for testing intergranular corrosion susceptibility in austenitic stainless steels | Corrosion-resistant testing for use in harsh chemical or food processing environments | Not applicable to thickness, specific to corrosion testing |

| ASTM A312 | Standard Specification for Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipes | Primarily for seamless, welded, and cold-worked pipes, related to plate applications for pipe connections | Used in plumbing, piping systems, or connections where plates may be involved | Typically for pipes, not plate material |

| ASTM A240/A240M-22 | Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for High-Temperature Service | Grades for high-temperature conditions, such as 316L, 310S, 347 alloys | Used in high-temperature environments like pressure vessels, boilers, heat exchangers, etc. | Common thickness: 0.5mm to 100mm, suitable for high-temp requirements |

Packing method: Packing according to customer's requirement.

| Category | Details |

| Packaging Methods | Bale packing, bare packing, frame, and pallet are adopted. |

| Packaging Standards | The following national standards are implemented (specify additional requirements if needed): |

| Standard | Description |

| GB/T191 | Package storage and transportation schematic mark. |

| GB/T4857 (all parts) | Basic tests for transport packages. |

| GB/T4879 | Rust-proof packaging. |

| GB/T5048 | Damp-proof packaging. |

| GB/T7350 | Waterproof packaging. |

| GB/T8166 | Buffer packaging design. |

| GB/T4892-1996 | Dimensions series for rigid square transport packages. |

| GB/T13201-91 | Dimensions series for cylindrical transport packages. |

Company Advantages

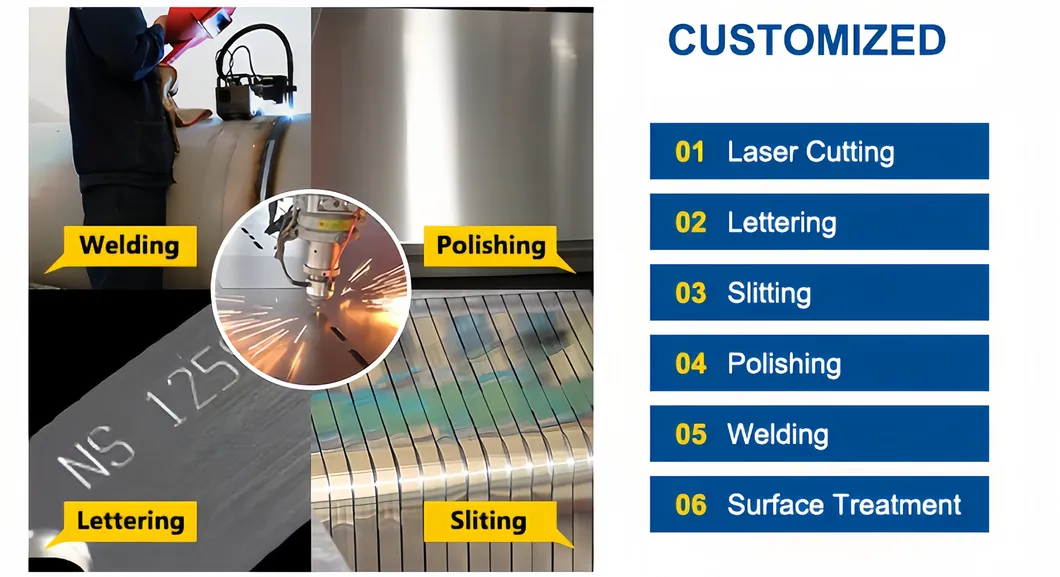

1. We are a large-scale production enterprise integrating production, research and development, and can customize the products required by customers.

2. We have a perfect after-sales service system, which can track the problems encountered by customers in production at any time and provide corresponding technical support, so as to share our high-quality resources with customers.

3. After more than ten years of development, the company has complete product varieties and large inventory, which can be delivered in the shortest time.

4. Free samples are available.

5. With obvious price advantage, the company has complete production process, from raw materials to finished products integrated production can maximize the cost savings.

We have a large stock and delivery time is 7 to 14 days after rec

RELATED PRODUCTS

ONLINE MESSAGE

CONTACT US

PROVIDE YOU WITH FREE SOLUTIONS