Welcome to Wuxi Hongye New Material Co., Ltd !

Tel : +86 180 1478 0128 Email:info@hongye-metal.com

2507 Duplex Stainless Steel Coil

Category:

Stainless Steel Coil

Width: 600mm – 2000mm, the narrowed products pls check in strip products

Max coil weight: 40MT, etc.

Coil ID: 508mm,610mm, etc.

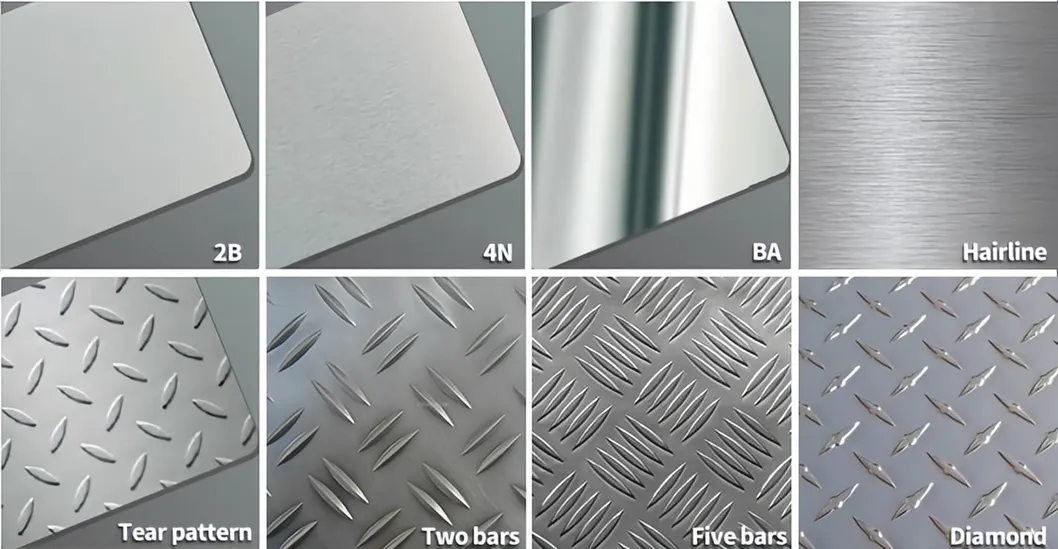

Finish: NO.1, 1D, 2D, #1, hot rolled finished, black, Anneal and pickling, mill finish

2507 Stainless Steel Coil Strip Specifications:

|

Grades |

Stainless Steel J1, J2, J4, 201, 202, 301, 304, 304H, 304L , 309, 309S, 310, 310S, 316, 316L, 316TI, 321, 321H, 347, 409, 410, 410S, 420, 430, 441, 904L |

|

Thickness |

0.2mm - 60mm |

|

Width |

3.2mm - 2000mm |

|

Length |

AS PER CUSTOMER'S REQUIREMENT |

|

Type of Material |

STAINLESS STEEL SOFT, DEEP DRAW, EXTRA DEEP DRAW, QUARTER HARD, HALF HARD,FULL HARD. |

|

Finish |

NO.1, 2B, 2D, 2H, 2R, No.4, HAIRLINE, SCOTCH BRITE, SATIN FINISH, NO.8, BA. |

|

Standard |

ASME, ASTM, AISI, EN, BS, GB, DIN, JIS, SUS, etc. |

|

Manufacture |

Cold Rolled ,hot rolled |

|

Density |

7.93g/cm3 |

|

Application |

Decoration,Industry,food processing and medical industry ,ships building industry etc. |

|

Certification |

SGS, BV, IQI, TUV, ISO, CE, etc |

|

Coil Weight |

3-10 Tons Or As Your Requirements |

|

Tolerance |

±1% |

|

MOQ |

1 ton |

|

Supply Ability |

5000 tons / month |

|

Lead Time |

7-15 working days after the receipt of 30% deposit |

|

Payment Terms |

30%T/T Advance + 70% Balance |

|

Price Terms |

FOB, CFR, CIF, EXW |

|

Packing |

Standard sea-worthy package or as required |

2507 Stainless Steel Same grade from different mill standard

S32750 00Cr25Ni7Mo4N 022Cr25Ni7Mo4N 1.4410

Chemical Composition of 2507 Stainless Steel Coil:

C |

Si |

Mn |

Cr |

Ni |

S |

P |

Mo |

Cu |

N |

|

≤0.03 |

≤0.8 |

≤2.0 |

24.0~26.0 |

6.0~8.0 |

≤0.02 |

≤0.035 |

3.0~5.0 |

< 0.5 |

0.24~0.35 |

2507 Super Duplex Stainless Steel Coils Applications

Cargo tanks

Fittings

Heat exchangers

Hot water tanks

Hydraulic piping

Lifting and pulley equipment

Propellers

Shafts

Spiral wound gaskets

Storage vessels

Water heaters, etc.

|

Surface Finish |

Definition |

Application |

|

2B |

Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. |

Medical equipment, Food industry, Construction material, Kitchen utensils. |

|

BA |

Those processed with bright heat treatment after cold rolling. |

Kitchen utensils, Electric equipment, Building construction. |

|

NO.3 |

Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. |

Kitchen utensils, Building construction. |

|

NO.4 |

Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. |

Kitchen utensils, Building construction, Medical equipment. |

|

HL |

Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. |

Building Construction. |

|

NO.1 |

The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. |

Chemical tank, pipe. |

|

Grade |

201/202/301/303/304/304L/316/316L/321/310S/401/409/410/420J1/420J2/430/439/443/444/2205/2507/904L.Etc |

|||

|

Surface Finish |

2B, BA, NO.1, NO.4, 8K, HL, Embossing, Satin, Mirror, ect |

|||

|

Standard |

JIS/SUS/GB/DIN/ASTM/AISI/EN |

|||

|

Technique |

Cold Rolled; Hot Rolled |

|||

|

Thickness |

0.3-4mm cold rolled; 3-16mm hot rolled; 16-100mm hot rolled; Customized according to customer requirements |

|||

|

Width |

1000mm, 1219mm, 1240mm, 1500mm, 1800mm, 2000mm |

|||

|

Length |

2000mm, 2438mm, 2500mm, 3000mm, 6000mm or as required |

|||

|

Color |

Golden, Black, Sapphire Blue, Brown, Rose Gold, Bronze, Silver, ect |

|||

|

Application |

Interior/Exterior decoration; Architectur; Evevator; Kitchen; Ceiling; Cabinet; Advertising nameplate; Roof structure; |

|||

|

Lead Time |

7-15 working days after the receipt of 30% deposit |

|||

|

Payment Terms |

30% TT for deposit,70% TT /70% LC at sight balance before shipment |

|||

|

Price Terms |

FOB, EXW, CIF, CFR |

|||

|

Packing |

Wooden Pallet or according to customer's requirements |

|||

|

Grade |

C |

Si |

Mn |

P |

S |

Ni |

Cr |

Mo |

|

201 |

≤0 .15 |

≤0 .75 |

5. 5-7. 5 |

≤0.06 |

≤ 0.03 |

3.5 -5.5 |

16 .0 -18.0 |

- |

|

202 |

≤0 .15 |

≤1.0 |

7.5-10.0 |

≤0.06 |

≤ 0.03 |

4.0-6.0 |

17.0-19.0 |

- |

|

301 |

≤0 .15 |

≤1.0 |

≤2.0 |

≤0.045 |

≤ 0.03 |

6.0-8.0 |

16.0-18.0 |

- |

|

302 |

≤0 .15 |

≤1.0 |

≤2.0 |

≤0.035 |

≤ 0.03 |

8.0-10.0 |

17.0-19.0 |

- |

|

304 |

≤0 .008 |

≤1.0 |

≤2.0 |

≤0.045 |

≤ 0.03 |

8.0-10.5 |

18.0-20.0 |

- |

|

304L |

≤0.03 |

≤1.0 |

≤2.0 |

≤0.035 |

≤ 0.03 |

9.0-13.0 |

18.0-20.0 |

- |

|

309S |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.045 |

≤ 0.03 |

12.0-15.0 |

22.0-24.0 |

- |

|

310S |

≤0.08 |

≤1.5 |

≤2.0 |

≤0.035 |

≤ 0.03 |

19.0-22.0 |

24.0-26.0 |

- |

|

316 |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.045 |

≤ 0.03 |

10.0-14.0 |

16.0-18.0 |

2.0-3.0 |

|

316L |

≤0.03 |

≤1.0 |

≤2.0 |

≤0.045 |

≤ 0.03 |

12.0 - 15.0 |

16 .0 -1 8.0 |

2.0 -3.0 |

|

321 |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.035 |

≤ 0.03 |

9.0 - 13 .0 |

17.0 -19.0 |

- |

|

630 |

≤0.07 |

≤1.0 |

≤1.0 |

≤0.035 |

≤ 0.035 |

3.0-5.0 |

15.5-17.5 |

- |

|

631 |

≤0.09 |

≤1.0 |

≤1.0 |

≤0.030 |

≤0.035 |

6.50-7.75 |

16.0-18.0 |

- |

|

904L |

≤2.0 |

≤0.045 |

≤1.0 |

≤0.035 |

- |

23.0·28.0 |

19.0-23.0 |

4.0-5.0 |

|

2205 |

≤0.03 |

≤1.0 |

≤2.0 |

≤0.030 |

≤0.02 |

4.5-6.5 |

22.0-23.0 |

3.0-3.5 |

|

2507 |

≤0.03 |

≤0.8 |

≤1.2 |

≤0.035 |

≤0.02 |

6.0-8.0 |

24.0-26.0 |

3.0-5.0 |

|

2520 |

≤0.08 |

≤1.5 |

≤2.0 |

≤0.045 |

≤0.03 |

0.19 -0. 22 |

0.24 -0.26 |

- |

|

410 |

≤0.15 |

≤1.0 |

≤1.0 |

≤0.035 |

≤0.03 |

- |

11.5-13.5 |

- |

|

430 |

≤0.1 2 |

≤0.75 |

≤1.0 |

≤ 0.040 |

≤0.03 |

≤0.60 |

16.0 -18.0 |

- |

| Stainless Steel(austenitic type) | ||||||||||

| USA | Germany | CHINA | Japan | Great Britain | France | Italy | Spain | Sweden | ||

| AISI/SAE | W.-nr. | DIN | GB | JIS | BS | EN | AFNOR | UNI | UNE | SS |

| 304L | 1.4306 | X2CrNi1911 | 0Cr19Ni10 | SUS340L | 304S11 | - | Z2CN18.10 | X2CrNi18.11 | - | 2352 |

| 304 | 1.435 | X5CrNi189 | 0Cr18Ni9 | SUS304 | 304S11 | 58E | Z6CN18.09 | X5CrNi1810 | F.3551/F.3541/F.3504 | 2332 |

| 303 | 1.4305 | X12CrNiS188 | 1Cr18Ni9MoZr | SUS303 | 303S21 | 58M | Z10CNF18.09 | X10CrNiS18.09 | F.3508 | 2346 |

| 301 | 1.431 | X12CrNi177 | Cr17Ni7 | SUS301 | - | - | Z12CN17.07 | X12CrNi1707 | F.3517 | 2331 |

| 316 | 1.4401 | X5CrNiMo1810 | 0Cr17Ni11Mo2 | SUSU316 | 316S16 | 58J | Z6CND17.11 | X5CrNiMo1712 | F.3543 | 2347 |

| 316LN | 1.4429 | X2CrNiMoN1813 | 0Cr17Ni13Mo | SUSU316LN | - | - | Z2CND17.13 | - | - | 2375 |

| 316LN | 1.4435 | X2CrNiMo1812 | 0Cr27Ni12Mo3 | SCS16/SUS316L | 316S13 | - | Z2CND17.12 | X2CrNiMo1712 | - | 2353 |

| 317L | 1.4438 | X2CrNiMo1816 | 0Cr19Ni13Mo | SUS317L | 317S12 | - | Z2CND19.15 | X2CrNiMo1816 | - | 2367 |

| 321 | 1.4541 | X10CrNiTi189 | 1Cr18Ni9Ti | SUS321 | 321S12 | 58B | Z6CNT18.10 | X6CrNiTi1811 | F.3553/F.3523 | 2337 |

| 347 | 1.455 | X10CrNiNb189 | 1Cr18Ni11Nb | SUS347 | 347S17 | 58F | Z6CNNb18.10 | X6CrNiNb1811 | F.3552/F.3524 | 2338 |

| 316Ti | 1.4571 | X10CrNiMoTi1810 | Cr18Ni12Mo2T | - | 320S17 | 58J | Z6CNDT17.12 | X6CrNiMoTi1712 | F.3535 | 2350 |

| 309 | 1.4828 | X15CrNiSi2012 | 1Cr23Ni13 | SUH309 | 309S24 | - | Z15CNS20.12 | X6CrNi2520 | - | - |

| 310S | 1.4845 | S12CrNi2521 | 0Cr25Ni20 | SUH310 | 310S24 | - | Z12CN2520 | X6CrNi2520 | F.331 | 2361 |

| 321 | 1.4878 | X12CrNiti189 | 1Cr18Ni9Ti | SUS321 | 321S32 | 58B,58C | Z6CNT18.12B | X6CrNiTi1811 | F.3523 | - |

| Stainless Steel(Ferrite type/Martensitic type) | ||||||||||

| USA | Germany | CHINA | Japan | Great Britain | France | Italy | Spain | Sweden | ||

| AISI/SAE | W.-nr. | DIN | GB | JIS | BS | EN | AFNOR | UNI | UNE | SS |

| 403 | 1.4 | X7Cr13 | 0Cr13/1Cr12 | SUS403 | 403S17 | - | Z6C13 | X6Cr13 | F.3110 | 2301 |

| 410 | 1.4006 | X10Cr13 | 1Cr13 | SUS410 | 410S21 | 56A | Z10C14 | X12Cr13 | F.3401 | 2302 |

| 430 | 1.4016 | X8Cr17 | 1Cr17 | SUS430 | 430S15 | 60 | Z8C17 | X8Cr17 | F.3113 | 2320 |

| - | 1.4034 | X46Cr13 | 4Cr13 | SUS420J2 | 420S45 | 56D | Z40CM/Z38C13M | X40Cr14 | F.3405 | 2304 |

| 431 | 1.4057 | X22CrNi17 | 1Cr17Ni2 | SUS431 | 431S29 | 57 | Z15CNi6.02 | X16CrNi16 | F.3427 | 2321 |

| 430F | 1.4104 | X12CrMoS17 | Y1Cr17 | SUS430F | - | - | Z10CF17 | X10CrS17 | F.3117 | 2383 |

| 434 | 1.4113 | X6CrMo17 | 1Cr17Mo | SUS434 | 434S17 | - | Z8CD17.01 | X8CrMo17 | - | 2325 |

| 405 | 1.4724 | X10CrA113 | 0Cr13AI | SUS405 | 403S17 | - | Z10C13 | X10CrA112 | F.311 | - |

| 430 | 1.4742 | X10CrA118 | Cr17 | SUS430 | 430S15 | 60 | Z10CAS18 | X8Cr17 | F.3113 | - |

| EV8 | 1.4871 | X53CrMnNiN219 | 5Cr2Mn9Ni4N | SUH35 | 349S54 | - | Z52CMN21.09 | X53CrMnNiN219 | - | - |

| ASTM Specification | Description | Applicable Grades/Materials | Main Applications | Common Thickness |

| ASTM A240 / A240M | Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip | Includes grades like 304, 304L, 316, 316L, 310S, 321, 410, 420, 430, etc. | General applications, pressure vessels, food processing equipment, etc. | Thickness: 0.5mm to 100mm, finishes: cold-rolled, hot-rolled, polished, etc. |

| ASTM A480 / A480M | General Requirements for Flat-Rolled Stainless and Heat-Resisting Steel Plate, Sheet, and Strip | Covers flat plates, sheets, and strips of stainless steel | General requirements for size, tolerances, mechanical properties, etc. | Thickness: Typically 0.5mm to 100mm, different surface finishes |

| ASTM A262 | Practice for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels | Primarily used for testing intergranular corrosion susceptibility in austenitic stainless steels | Corrosion-resistant testing for use in harsh chemical or food processing environments | Not applicable to thickness, specific to corrosion testing |

| ASTM A312 | Standard Specification for Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipes | Primarily for seamless, welded, and cold-worked pipes, related to plate applications for pipe connections | Used in plumbing, piping systems, or connections where plates may be involved | Typically for pipes, not plate material |

| ASTM A240/A240M-22 | Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for High-Temperature Service | Grades for high-temperature conditions, such as 316L, 310S, 347 alloys | Used in high-temperature environments like pressure vessels, boilers, heat exchangers, etc. | Common thickness: 0.5mm to 100mm, suitable for high-temp requirements |

Packing method: Packing according to customer's requirement.

| Category | Details |

| Packaging Methods | Bale packing, bare packing, frame, and pallet are adopted. |

| Packaging Standards | The following national standards are implemented (specify additional requirements if needed): |

| Standard | Description |

| GB/T191 | Package storage and transportation schematic mark. |

| GB/T4857 (all parts) | Basic tests for transport packages. |

| GB/T4879 | Rust-proof packaging. |

| GB/T5048 | Damp-proof packaging. |

| GB/T7350 | Waterproof packaging. |

| GB/T8166 | Buffer packaging design. |

| GB/T4892-1996 | Dimensions series for rigid square transport packages. |

| GB/T13201-91 | Dimensions series for cylindrical transport packages. |

Company Advantages

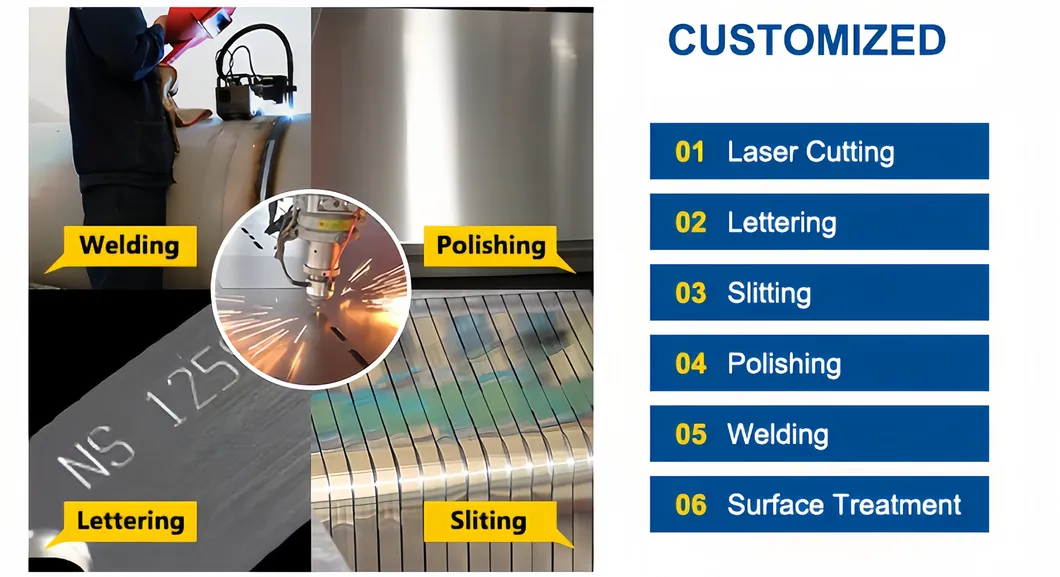

1. We are a large-scale production enterprise integrating production, research and development, and can customize the products required by customers.

2. We have a perfect after-sales service system, which can track the problems encountered by customers in production at any time and provide corresponding technical support, so as to share our high-quality resources with customers.

3. After more than ten years of development, the company has complete product varieties and large inventory, which can be delivered in the shortest time.

4. Free samples are available.

5. With obvious price advantage, the company has complete production process, from raw materials to finished products integrated production can maximize the cost savings.

We have a large stock and delivery time is 7 to 14 days after rec

RELATED PRODUCTS

ONLINE MESSAGE

CONTACT US

PROVIDE YOU WITH FREE SOLUTIONS