Welcome to Wuxi Hongye New Material Co., Ltd !

Tel : +86 180 1478 0128 Email:info@hongye-metal.com

1070 Aluminum pipe

Category:

Aluminum pipe

Make use of its advantages to manufacture some structural parts with specific performance, such as aluminum foil gaskets and capacitors, electronic tube isolation net, wire, cable protection sleeve, net, wire core and aircraft ventilation system parts and decorative parts.

About the aluminum

1070 aluminum has high plasticity, corrosion resistance, electrical conductivity and good thermal conductivity, but low strength, not through heat treatment to strengthen, cutting is not good, can accept contact welding, gas welding. Make use of its advantages to manufacture some structural parts with specific performance, such as aluminum foil gaskets and capacitors, electronic tube isolation net, wire, cable protection sleeve, net, wire core and aircraft ventilation system parts and decorative parts. And 1070 aluminum similar to ask 1070A aluminum, industrial pure aluminum, with the general characteristics of aluminum, small density, good electrical and thermal conductivity, corrosion resistance, good plastic processing performance, can be processed into plate, belt, foil and extruded products, can be gas welding, argon arc welding, spot welding. Industrial pure aluminum cannot be strengthened by heat treatment, but its strength can be improved by cold deformation, and the only form of heat treatment is annealing.

Aluminum is a silver-white light metal, relatively soft, density 2.7g/cm3, melting point 660.4℃, boiling point 2467℃, aluminum and aluminum alloys have many excellent physical properties, has been very widely used. Aluminum has good reflection performance of light, reflecting ultraviolet light is stronger than silver, the purer aluminum is, its reflection ability is better, and the method of vacuum aluminum plating is commonly used to make high-quality mirrors. Vacuum aluminized film combined with polysilicon film becomes a cheap and lightweight solar cell material. Aluminum powder can maintain a silvery luster, often used to make paint, commonly known as silver powder. Pure aluminum conducts electricity very well, second only to silver and copper. In the electric power industry, it can replace part of copper for wires and cables. Aluminum is a good conductor of heat. It can be used to make various heat exchangers, heat dissipating materials and civil cookers in industry. Aluminum has good ductility, can be drawn into a fine wire, rolled into a variety of aluminum products, but also can be made into thinner than 0.01mm aluminum foil, widely used in packaging cigarettes, candy, etc.. Aluminum alloy has some better properties than pure aluminum, which greatly expands the application range of aluminum. For example, pure aluminum is soft, when a certain amount of copper, magnesium, manganese and other metals are added to aluminum, the strength can be greatly improved, almost equivalent to steel, and the density is small, not easy to rust, widely used in aircraft, cars, trains, ships, artificial satellites, rockets manufacturing. At -196 ° C, some steel is as brittle as glass, while some aluminum alloys increase in strength and toughness, making them cheap and lightweight cryogenic materials that can be used to store liquid oxygen and hydrogen for rocket fuel.

PRODUCT

| Shape: | Round |

| Length: | Customized, 1000mm-12000mm or customized |

| Wall Thickness: | 1-80mm |

| Processing Service: | Bending, Decoiling, Welding, Punching, Cutting |

| Type: | OEM ODM |

| Standard: | GB, ASTM, EN, JIS, AISI, DIN |

| Application: | Rail transit, automobile, electronics, electrics and other indust |

| Surface Treatment: | Mill Finished |

| Usage: | Industrial |

| Temper: | T3 - T8 |

| Model Number: | Customized |

| Tolerance: | ±1% |

| Delivery Time: | 15-21 days |

| Diameter: | 10mm-400mm |

| Certification: | CE, ISO9001, ISO14001, ISO45001, IATF16949 |

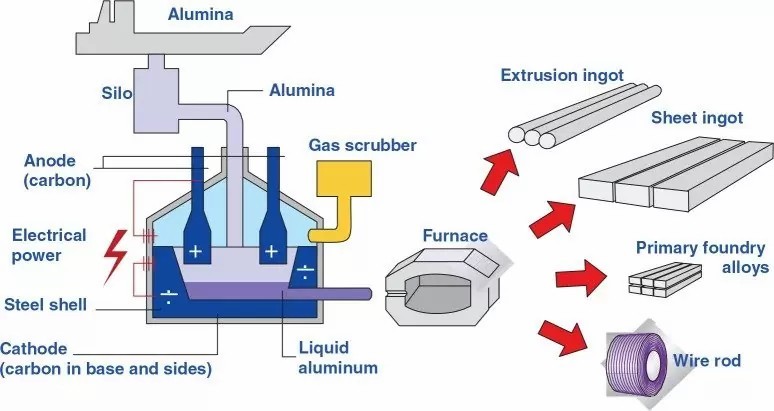

Aluminum Production Process

Factory profile

Wuxi Hongye New Material Co., Ltd. is a leading stainless steel, aluminum and metal material processing and manufacturing enterprise in China. It has been in China for 12 years. Since 2010, it has started to arrange the manufacturing and sales of stainless steel and metal materials in Chinese Mainland. The company has more than 1300 employees, covers an area of 720000 square meters, has a total of 12 Kaiping and slitting equipment, and 113 bending, shearing, welding, laser equipment, surface treatment equipment, etc, The standing stock is more than 70000 tons, and the materials are mainly sold to more than 150 government enterprises in China. It is the designated long-term partner of Chinese government enterprises and is strongly supported by the government.

Packing method: Packing according to customer's requirement.

It can also be packed according to the national packaging standards:

1.1 Bale packing, bare packing, frame and pallet are adopted.

1.2 Packaging standards: The following national standards shall be implemented (the part exceeding the requirements shall be specified separately)

GB/T191 package storage and transportation schematic mark

GB/T4857 (all parts) transport package basic test

GB/T4879 rust proof packaging

GB/T5048 damp proof packing

GB/T7350 waterproof packaging

GB/T8166 buffer packaging design

GB/T4892-1996 Rigid square transport package dimensions series

GB/T13201-91 Cylinder transport package size series

Company Advantages

1. We are a large-scale production enterprise integrating production, research and development, and can customize the products required by customers.

2. We have a perfect after-sales service system, which can track the problems encountered by customers in production at any time and provide corresponding technical support, so as to share our high-quality resources with customers.

3. After more than ten years of development, the company has complete product varieties and large inventory, which can be delivered in the shortest time.

4. Free samples are available.

5. With obvious price advantage, the company has complete production process, from raw materials to finished products integrated production can maximize the cost savings.

RELATED PRODUCTS

ONLINE MESSAGE

CONTACT US

PROVIDE YOU WITH FREE SOLUTIONS